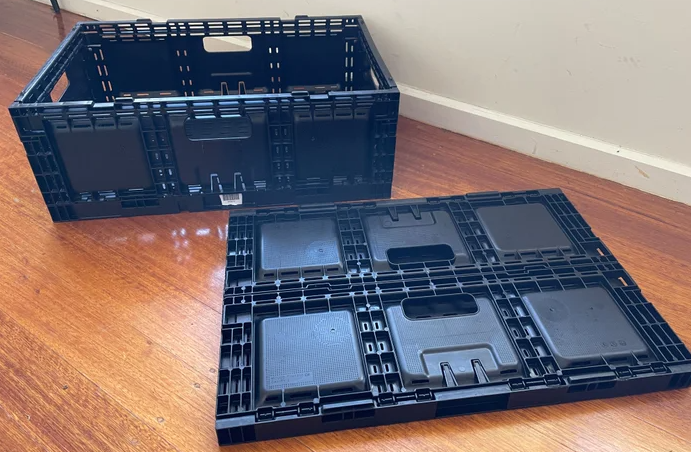

Across Australia’s diverse economy, durable and reusable storage solutions play a critical role in keeping goods moving safely and efficiently. Among the most widely adopted options are plastic crates, valued for their strength, hygiene, and adaptability. From farms and factories to supermarkets and warehouses, these containers support daily operations in ways that improve productivity, reduce waste, and meet strict industry standards. Understanding how they are used across sectors highlights why they have become such an essential part of modern Australian industry.

Australia’s geographic scale, climate extremes, and focus on sustainability all influence how goods are handled and transported. Businesses require solutions that can withstand heat, moisture, and repeated handling while remaining cost-effective. This is where plastic crates have found a natural fit, replacing many traditional materials and offering long-term operational benefits.

Agriculture and Fresh Produce Handling with plastic crates

In the agricultural sector, reliable produce handling is essential from harvest through to distribution. Farmers and growers use plastic crates extensively for collecting, storing, and transporting fruits, vegetables, and other fresh goods. Their rigid structure protects delicate produce from crushing, while ventilation features help maintain airflow and freshness during transit.

Unlike wooden alternatives, these containers do not splinter or absorb moisture, which is particularly important in Australia’s varied climates. They are easy to wash and sanitise, helping farms meet food safety regulations and reduce the risk of contamination. Stackable designs also allow for efficient use of space in sheds, trucks, and cold storage facilities, which is crucial during peak harvest seasons when volumes are high and time is limited.

Food and Beverage Processing Using plastic crates

The food and beverage industry demands strict hygiene and consistent handling standards. In processing plants and distribution centres, plastic crates are commonly used to move raw ingredients, packaged products, and finished goods between different stages of production. Their smooth, non-porous surfaces make cleaning straightforward, supporting compliance with Australian food safety requirements.

In beverage manufacturing, these containers are often used to transport bottles and cans, offering stability and protection against breakage. Their uniform size allows for seamless integration with automated systems, such as conveyor belts and robotic handling equipment. This compatibility helps manufacturers streamline operations, reduce downtime, and maintain consistent output, even during periods of high demand.

Retail, Warehousing, and Logistics with plastic crates

Retailers and logistics providers rely on efficient stock movement to keep shelves full and customers satisfied. Within this space, plastic crates are widely used for back-of-house storage, order picking, and last-mile delivery. Their lightweight nature reduces manual handling strain for workers, while their durability ensures they can be reused across countless delivery cycles.

In large distribution centres, standardised containers improve inventory control by allowing goods to be sorted, stacked, and tracked more easily. Many retailers also use collapsible designs, which save space when empty and reduce return transport costs. For Australia’s vast supply chains, where goods often travel long distances between cities and regional areas, these efficiencies translate into significant time and cost savings.

See also: Rent Convertible Dubai: Drive in Style and Experience Freedom

Manufacturing, Sustainability, and the Role of plastic crates

In manufacturing environments, plastic crates support the safe movement of components, tools, and finished products. Automotive, electronics, and industrial manufacturers use them to protect parts from damage and to maintain organised workflows on the factory floor. Colour-coded options further enhance efficiency by helping workers quickly identify contents or production stages.

Sustainability is another key factor driving their adoption across Australian industries. Reusable containers help reduce reliance on single-use packaging, aligning with corporate environmental goals and national waste reduction initiatives. Many are made from recyclable materials and designed for long service lives, making them a practical choice for businesses aiming to balance performance with environmental responsibility.

A Versatile Solution Across the Economy

From paddocks and processing plants to retail outlets and factories, the widespread use of plastic crates reflects their versatility and reliability. They support hygiene, efficiency, and sustainability across multiple sectors, adapting easily to Australia’s unique operational challenges. As industries continue to modernise and focus on smarter logistics and environmental outcomes, these containers are likely to remain a cornerstone of Australian supply chains for years to come.

Conclusion

Plastic crates play a vital role across Australian industries by providing a durable, hygienic, and sustainable storage solution. Their widespread use in agriculture, food processing, retail, logistics, and manufacturing highlights their adaptability to different operational needs. By improving efficiency, protecting goods, and reducing waste, plastic crates support smoother supply chains and help businesses meet modern safety and environmental standards throughout Australia.