In a crowded marketplace, small businesses need distinctive, cost-effective branding to capture attention and build customer loyalty. Whether it’s a local boutique, a handmade candle seller, or a home-based gift shop, the way products look on the shelf directly influences buying decisions. Traditional branding methods like vinyl decals, paper labels, or screen printing can be slow, material-limited, and expensive to scale.

This is where UV DTF transfers offer a practical advantage.

UV DTF (Direct-to-Film) technology enables vivid, full-color designs to be applied to many hard surfaces without large machines or complex production steps. With tools such as a UV DTF gangsheet builder, businesses can arrange multiple graphics on one sheet to save cost and streamline usage. In addition, UV DTF stickers provide a durable, premium-looking alternative to standard labels.

Here’s how this m ethod is helping small brands upgrade their product presentation with minimal investment.

Understanding UV DTF Transfers

UV DTF transfers involve printing artwork onto a specialty film using UV-curable inks. The printed layer is then adhered directly to surfaces like glass, plastic, acrylic, metal, or wood. Unlike heat-based processes, no heat press is required. The transfer is positioned, pressed into place, and the carrier film is removed.

The result is a bright, long-lasting print that resists scratches, moisture, and fading. For small businesses, this means moving beyond fragile paper labels and achieving a finish that looks professionally manufactured.

Branding Without Heavy Equipment Costs

A major barrier for small businesses is the price of professional printing equipment. UV printers, engraving tools, and cutting machines can require significant upfront investment. With UV DTF transfers, businesses skip this entirely.

They can order pre-made transfers, organize designs using a UV DTF gangsheet builder, and apply them manually. No technical training or expensive setup is needed. This lowers the entry barrier and allows entrepreneurs to brand products at a professional level from day one.

Suitable for Many Product Types

While traditional DTF transfer is excellent for textiles, UV DTF is designed for hard materials. This expands branding options across numerous items, such as:

- Drinkware like tumblers and mugs

- Glass jars and bottles

- Phone cases and tech accessories

- Candle holders and cosmetic containers

- Gift packaging and boxes

- Acrylic signage and wooden crafts

This versatility helps small brands maintain consistent visual identity across all merchandise.

Upgrading Labels with UV DTF Stickers

Many small brands rely on paper labels or basic stickers that may peel, wrinkle, or fade. UV DTF stickers provide a more durable solution. They are waterproof, scratch-resistant, and appear as though printed directly onto the product.

For instance, a handmade soap or candle business can apply UV DTF stickers to glass containers, instantly improving the product’s shelf appeal without increasing packaging expenses.

See also: Technology and Digital Identity

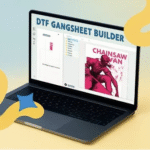

Saving Money with a UV DTF Gangsheet Builder

A UV DTF gangsheet builder allows multiple logos, labels, or graphics to be placed on a single sheet. This reduces unused space and lowers the cost per piece.

Small businesses often require various logo sizes for different items. Instead of ordering separate prints, they can combine everything into one organized sheet. This is particularly helpful for:

- Limited product runs

- Seasonal packaging updates

- Personalized customer orders

- Diverse product catalogs

It keeps branding efficient and budget-friendly.

Ideal for Print-on-Demand and Small Runs

Small businesses typically don’t operate in high volumes. They benefit from flexibility. UV DTF transfers support a print-on-demand approach where products are branded only when needed.

There’s no requirement to pre-print packaging or maintain large stocks of labeled items. Businesses can keep plain inventory and apply branding as orders arrive, reducing waste and storage costs.

Long-Lasting and Reliable Prints

Durability is essential for items like drinkware, cosmetic packaging, or outdoor goods. UV DTF transfers hold up against moisture, handling, and everyday wear. When customers see that branding remains intact over time, it strengthens trust in the product’s quality.

Quick and Simple Application

The application process is straightforward and fast:

- Peel the backing film

- Position the transfer on the item

- Press gently to adhere

- Remove the top layer

No heat, drying time, or special tools are involved. This allows businesses to prepare multiple products quickly, which is especially valuable during busy periods.

Encouraging Creative Branding

Small brands often differentiate themselves through creativity. UV DTF transfers allow detailed artwork, gradients, fine text, QR codes, and colorful logos without production limitations.

This makes it easier to display brand identity, contact information, and visual storytelling directly on the product surface.

Helping Small Brands Compete with Larger Companies

Professional presentation is no longer exclusive to large manufacturers. UV DTF transfers enable even home-based businesses to create items that look retail-ready.

Since customers often judge products by appearance, improved branding enhances perceived value and builds confidence in the brand.

Conclusion

UV DTF transfers are reshaping how small businesses approach product branding. Without the need for expensive machinery, and with the advantages of a UV DTF gangsheet builder and durable UV DTF stickers, brands can decorate a wide variety of products affordably and efficiently.

This method supports flexible production, reduces waste, and delivers a high-quality finish on hard surfaces. For small businesses aiming to elevate their brand image without major investment, UV DTF technology offers a practical and powerful solution.