In custom printing, operational efficiency depends on speed, precision, and the ability to work across different materials. While fabric decoration has long relied on traditional DTF transfer methods, UV DTF transfers have introduced a practical way to decorate rigid surfaces such as glass, acrylic, metal, wood, plastic, and ceramics. This shift allows apparel brands, gift retailers, print providers, and boutiques to expand beyond garments into high-margin merchandise.

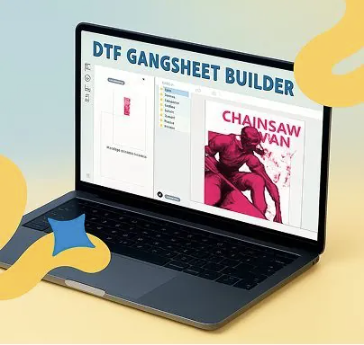

As orders diversify, businesses often juggle many small graphics—logos, labels, decals, and tags—destined for different products. Preparing these files individually can become disorganized and time-consuming. A UV DTF gangsheet builder addresses this problem by organizing multiple designs onto a single, optimized print layout. The result is faster preparation, less waste, and a smoother production cycle for hard surface applications.

This article explains how a UV DTF gangsheet builder improves efficiency and supports scalable hard goods printing.

UV DTF Transfers for Rigid Items

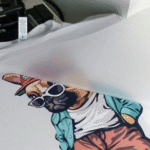

UV DTF prints are produced using UV-curable inks and applied with a peel-and-stick method. Unlike heat-based transfers for textiles, these prints adhere directly to solid materials without a press.

Common use cases include:

- Drinkware such as tumblers and mugs

- Phone cases and tech accessories

- Gift packaging and retail boxes

- Keychains and promotional items

- Glass containers and bottles

Because no heat is required, application is quick and consistent—ideal for bulk customization. However, when handling dozens of small artworks across orders, inefficient file setup can waste time and film. This is where the gangsheet builder becomes indispensable.

What a UV DTF Gangsheet Builder Does

A UV DTF gangsheet builder is a layout tool that lets users upload multiple artworks and automatically arrange them onto one print sheet. Instead of dedicating a sheet to a single design, many graphics are combined into a space-efficient layout.

This approach delivers:

- Reduced film waste

- Lower cost per print

- Quicker prepress preparation

- Cleaner organization for mixed orders

For print shops and brands entering hard goods decoration, this tool removes the need to manually arrange files in complex design software.

Removing Time-Consuming Manual Layout

Without automation, designers must place each element manually in tools like Illustrator or Photoshop. This process takes time and often leaves unusable gaps between graphics.

A gangsheet builder intelligently nests designs with minimal spacing, ensuring the printable area is used effectively. Over the course of a day, this can save hours in file preparation for businesses processing frequent custom jobs.

Processing Multiple Orders in a Single Print Run

B2B printers regularly manage varied requests such as:

- Dozens of logos for branded drinkware

- Small label batches for candle or soap makers

- Custom decals for gift shops

Rather than printing separate sheets for each order, all these graphics can be placed onto one gang sheet. The sheet is printed once, then designs are trimmed and sorted afterward.

This method allows a single print cycle to serve multiple clients, speeding up turnaround and simplifying job handling.

See also: Empowering Financial Institutions with Digital Lending Platforms in Australia

Cutting Waste and Lowering Production Costs

UV DTF film is a premium consumable, so inefficient layouts directly affect profitability. Empty spaces on a sheet mean higher cost per usable design.

By optimizing placement, a gangsheet builder reduces:

- Film waste

- Ink usage

- Overall production expense

This efficiency translates into better margins for businesses offering customized hard surface products.

Better Organization After Printing

When prints are arranged logically on a gang sheet, post-print tasks become easier to manage:

- Designs are grouped clearly

- Cutting follows a predictable pattern

- Sorting for individual orders is faster

This structured output reduces errors during packing and shipping—especially important during busy retail periods and promotional seasons.

Ideal for Print-on-Demand Merchandise

For businesses operating on a print-on-demand model, the gangsheet builder offers flexibility. There’s no need to wait for large volumes of the same design. Multiple small orders can be combined into one sheet and printed together.

This supports offerings such as:

- Personalized drinkware

- Customized gift items

- Short-run branded merchandise

All without holding large inventories.

Accessible to Teams Without Design Expertise

Not every shop employs a professional designer. A gangsheet builder simplifies the process so users only need to upload artwork and adjust sizing. The system handles spacing and layout automatically.

This ease of use reduces reliance on specialized skills and speeds up daily operations.

Enabling Confident Business Expansion

As demand grows for customized merchandise, businesses need systems that handle complexity without increasing workload. A UV DTF gangsheet builder allows companies to accept more orders, serve more clients, and decorate more products without complicating production.

This makes it easier to expand into:

- Corporate promotional products

- Boutique gift lines

- Event favors and wedding merchandise

- Branded retail packaging

All supported by the same efficient layout workflow.

Conclusion

Hard surface customization is rapidly expanding, and UV DTF transfers are central to this growth. To take full advantage of the technology, businesses must optimize how they prepare and print designs.

A UV DTF gangsheet builder replaces manual layout work, reduces material waste, speeds up processing, and brings structure to production. For apparel brands, print shops, and boutiques moving into hard goods, it is a practical tool that improves efficiency and profitability.

By incorporating this system into your workflow, you can produce more efficiently, minimize waste, and scale your hard surface printing operations with consistency and control.